Tamanho: 110.7 Mb

Tipo: PDF

Idioma: Inglês

Índice:

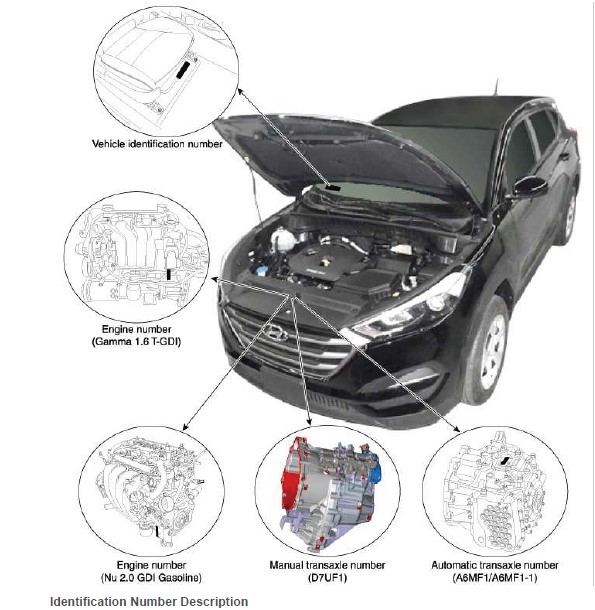

Hyundai Tucson TL 2015 – 1.6L WorkShop Manual

– General Information

– 4 Wheel Drive (4WD) System

– DCT (Dual Clutch Transmission) System

– Driveshaft and Axle

– Emission Control System

– Engine Control + Fuel System

– Engine Electrical System

– Engine Mechanical System

– Heating, Ventilation and Air Conditioning (HVAC)

– Suspension System

– Body (Interior and Exterior)

– Body Electrical System

– Brake System

– Restraint

– Steering System

Hyundai Tucson TL 2015 – 2.0L WorkShop Manual

– General Information

– Engine Mechanical System

– Engine Electrical System

– Emission Control System

– Engine Control + Fuel System

– Automatic Transaxle System

– 4 Wheel Drive (4WD) System

– Driveshaft and Axle

– Suspension System

– Steering System

– Restraint

– Brake System

– Body (Interior and Exterior)

– Body Electrical System

– Heating, Ventilation and Air Conditioning (HVAC)

– Engine D4FA

– EngineD4EA

https://loja.webautomotivo.com.br/produto/seja-um-associado/

Tamanho: 120.7 Mb

Tipo: PDF

Idioma: Inglês

Manual de serviço e operação para manutenção. Índice disponível nas imagens abaixo.

https://loja.webautomotivo.com.br/produto/seja-um-associado/

Tamanho: 64.4 Mb

Idioma: Português

Tipo: PDF

ÍNDICE

– Ficha técnica

– Cuidados especiais

– Diagrama geral

– Pinagem do Módulo de Injeção

– Check List

– Relés e Fusíveis

– Valores ideais

– Revisão rápida

– Módulo de comando Bosh MA 3.1

– Relé do sistema

– Sensor de oxigênio

– Sensor de temperatura do líquido de arrefecimento

– Sensor de temperatura do ar de admissão

– Atuador de marcha lenta

– Sensor de posição da borboleta de aceleração

– Eletro Injetor

– Bomba de combustível

– Eletro válvula de purga do cânister

– Sensor de posição da árvore de manivelas

– Bobina de ignição

– Sensor de velocidade

– Diagrama elétrico

https://loja.webautomotivo.com.br/produto/seja-um-associado/

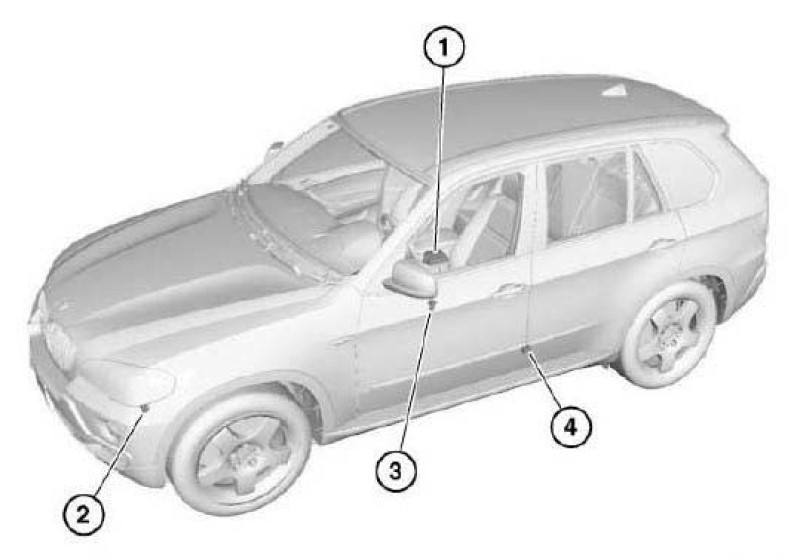

Tamanho: 166 Mb

Formato: PDF

Idioma: Inglês

Índice

repair update 2009-2010

ac wiring

anti lock brakes

audio navigation anti-theft repairs

auto trans repair

axle front repair

axle rear repair

body repair

brake fluids

brake pedal repair

Brakes

cooling system repair

cruise control

engine and gearbox suspension repair 6 cyl

engine and gearbox suspension repair 8 cyl

engine diagnosis

engine electrical repairs 6 cyl

engine electrical repairs 8 cyl

engine electrical torques

engine repairs 6 cyl

engine repairs 8 cyl

engine service 6 cyl

engine service 8 cyl

engine tech 6 cyl

engine tech 8 cyl

exhaust repair 6 cyl

exhaust repair v8

fuel supply system repair

fuel system 6 cyl

fuel system 8 cyl

general electric system repairs 6 cyl

general electric system repairs

hvac refrigerant

hvac repairs

instruments repair

lights repairs

propeller shaft repair

seat belts etc

seats repairs

special tools

starter

steering repair

sunroof

suspension systems integrated

transfer box repair

trouble codes

wheels and tires

Wiring part 1

wiring part 2

wiring part 3

wiring part 4

https://loja.webautomotivo.com.br/produto/seja-um-associado/

Tamanho: 717 Mb

Tipo: PDF

Idioma: Inglês

https://loja.webautomotivo.com.br/produto/seja-um-associado/

Índice

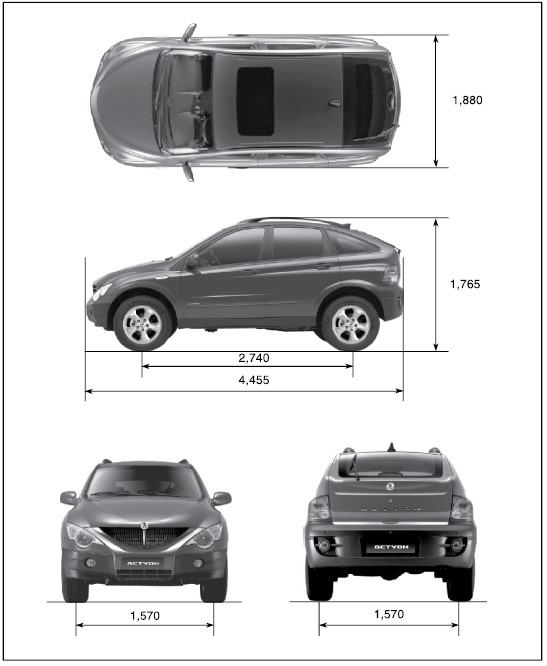

ACTYON 2008.07

GENERAL

1. DIMENSIONS

2. SPECIFICATIONS

3. VEHICLE IDENTIFICATION

4. MAINTENANCE INTERVAL

5. RECOMMENDED FLUIDS AND LUBRICANTS

6. JACK-UP POINTS (DOTTED CIRCLES)

7. PIN ARRANGEMENT OF DIAGNOSTIC CONNECTOR

8. ELECTRIC COMPONENTS AND LAYOUT

9. STANDARD BOLTS SPECIFICATIONS

ENGINE GENERAL

1. ENGINE ASSEMBLY LAYOUT

2. ENGINE CONTROLS LAYOUT

3. ELECTRICAL COMPONENTS AND PREHEATING SYSTEM

4. INTAKE SYSTEM LAYOUT

5. EXHAUST SYSTEM LAYOUT

6. LUBRICATION SYSTEM LAYOUT

7. COOLING SYSTEM LAYOUT

8. FUEL SYSTEM LAYOUT

9. FUEL SUPPLY SYSTEM

10. CLEANNESS

11. MAINTENANCE AND REPAIR

12. GUIDELINES FOR SERVICE WORK SAFETY

13. DURING SERVICE WORK FOR INSPECTION

14. DURING SERVICE WORK FOR ELECTRIC DEVICES

15. OWNER INSPECTIONS AND SERVICES

16. STANDARD BOLTS SPECIFICATIONS

CRUISE CONTROL SYSTEM

1. CRUISE CONTROL SWITCH

2. CIRCUIT DIAGRAM

3. HOW TO OPERATE CRUISE CONTROL SWITCH

ENGINE ASSEMBLY

– GENERAL

1. MAJOR COMPONENTS IN ENGINE AND ENGINE COMPARTMENT

2. SPECIFICATIONS AND PERFORMANCE CURVE

3. TIGHTENING TORQUE

CONFIGURATION AND FUNCTIONS

– CYLINDER HEAD

CAMSHAFT ASSEMBLY

TIMING CHAIN ASSEMBLY

CYLINDER BLOCK

CRANKSHAFT ASSEMBLY

FLYWHEEL

PISTON AND CONNECTING ROD

HIGH PRESSURE PUMP(HPP)

– REMOVAL AND INSTALLATION

GENERAL DIAGNOSIS

DIAGNOSTIC INFORMATION AND PROCEDURE

REMOVAL STEPS OF ENGINE ASSEMBLY

ENGINE ACCESSORIES

DISASSEMBLY AND REASSEMBLY OF ENGINE ASSEMBLY

ENGINE OVERHAUL

CYLINDER HEAD

INTAKE/EXHAUST

CAMSHAFT ASSEMBLY

TIMING CHAIN

CRANKSHAFT

PISTON AND CONNECTING ROD

DISASSEMBLY AND REASSEMBLY OF HIGH PRESSURE PUMP(HPP)

ENGINE FUEL SYSTEM

– GENERAL

1. CAUTIONS FOR DI ENGINE

– OVERVIEW AND OPERATION PROCESS

1. ELECTRONIC CONTROL OF FUEL SYSTEM

2. COMPOSITION OF FUEL SYSTEM

3. HYDRAULIC CYCLE IN FUEL LINE (TRANSFER AND HIGH PRESSURE LINE)

4. COMPONENTS OF LOW PRESSURE TRANSFER LINE

5. COMPONENTS OF HIGH PRESSURE TRANSFER LINE

6. CIRCUIT DIAGRAM

– CONFIGURATION AND FUNCTIONS

TRANSFER PUMP

INLET METERING VALVE(IMV)

HIGH PRESSURE PUMP

FUEL FILTER

PRIMING PUMP

HIGH PRESSURE ACCUMULATOR(COMMON RAIL)

FUEL PRESSURE SENSOR

FUEL TEMPERATURE SENSOR

INJECTOR

ENGINE INTAKE SYSTEM

– GENERAL

1. ENGINE INTAKE SPECIFICATIONS

– OVERVIEW AND OPERATION PROCESS

1. INTAKE SYSTEM LAYOUT

2. AIR FLOWS

– CONFIGURATION AND FUNCTIONS

AIR FLOW SENSOR (HOT FILM AIR MASS SENSOR)

INTERCOOLER

INTAKE MANIFOLD ASSEMBLY

– REMOVAL AND INSTALLATION

PRECAUTIONS WHEN INSTALLING INTAKE SYSTEM

AIR CLEANER ELEMENTREPLACEMENT

AIR CLEANER HOUSING

AIR FLOW SENSOR(HOT FILM AIR MASS SENSOR)

INTERCOOLER

INTAKE MANIFOLD

ENGINE EXHAUST SYSTEM

– GENERAL

1. INSPECTION BEFORE DIAGNOSIS

– OVERVIEW AND OPERATION PROCESS

1. EXHAUST SYSTEM LAYOUT

– CONFIGURATION AND FUNCTIONS

TUBO CHARGER ASSEMBLY

1913-01 VGT(VARIABLE GEOMETRY TUBOCHARGER)

EGR VALVE AND VACUUM MODULATOR

EXHAUST DEVICE AND MUFFLER

– REMOVAL AND INSTALLATION

DIAGNOSIS AND MAINTENANCE For TURBO CHARGER SYSTEM

PATH OF TUBO CHARGER DEFECT

HOW TO DIAGNOSE

PATH OF EXHAUST DEVICE DEFECT

TUBO CHARGER ASSEMBLY

TUBO CHARGER CHECK FOR VGT

EGR VALVE

VACUUM MODULATOR ASSEMBLY

EXHAUST MANIFOLD

EXHAUST PIPE

LUBRICATION SYSTEM

– GENERAL

1. SPECIFICATIONS

2. OIL PRESSURE SWITCH

– OVERVIEW AND OPERATION PROCESS

1. LAYOUT AND OVERVIEW

2. LUBRICATION DIAGRAM

– CONFIGURATION AND FUNCTIONS

OIL PUMP

BLOW-BY GAS REDUCTION DEVICE

CYLINDER HEAD COVER

OIL SEPARATOR

OIL SPRAY NOZZLE

OIL PAN ASSEMBLY

– REMOVAL AND INSTALLATION

TROUBLE DIAGNOSIS

ENGINE OIL CHANGE

ENINE OIL FILTER CHANGE

OIL FILTER AND COOLER

OIL DIPSTICK GUIDE TUBE

DISASSEMBLY OF OIL SPRAY NOZZLE

OIL PAN AND OIL PUMP

ENGINE COOLING SYSTEM

– GENERAL

1. ENGINE COOLING SPECIFICATIONS

– OVERVIEW AND OPERATION PROCESS

1. COMPONENTS OF ENGINE COOLING

2. COOLING SYSTEM FLOW

3. FUNCTION DESCRIPTION OF COOLING SYSTEM

– CONFIGURATION AND FUNCTIONS

RADIATOR

WATER PUMP

COOLANT RESERVOIR

THERMOSTAT

COOLANT TEMPERTURE SENSOR

PREHEATING SYSTEM

– REMOVAL AND INSTALLATION

TROUBLE DIAGNOSIS

COOLANT LEVEL CHECK

INSPECTION AND REPAIR

DRAINING AND ADDING OF COOLANT

COOLANT HOSE(INLET/OUTLET)

SHROUD AND COOLING FAN/CLUTCH

WATER PUMP ASSEMBLY

THERMOSTAT

WATER PUMP HOUSING

RADIATOR

REPLACEMENT OF FAN BELT

COOLANT RESERVOIR

PREHEATING

PREGLOW PLUG

ECU

– CONFIGURATION AND FUNCTIONS

ENGINE ECU – CDPF (EURO IV)

CONNECTOR PIN OF ENGINE ECU – CDPF (EURO IV)

ECU (ENGINE CONTROL UNIT – D20DT EU IV)

– REMOVAL AND INSTALLATION

ENGINE ECU – CDPF (EURO IV)

CDPF

– GENERAL INFORMATION

1. OVERVIEW FOR CDPF (EURO IV)

2. CDPF (EURO IV) SYSTEM

– OVERVIEW AND OPERATION PROCESS

1. OVERVIEW

2. CDPF (EURO IV) SYSTEM CONTROL

3. SOOT FILTERING AND BURNING PROCEDURES

4. COMPONENTS OF CDPF SYSTEM

– COMFIGURATION AND FUNCTIONS

FRONT EXHAUST GAS TEMPERATURE SENSOR – CDPF (EURO IV)

REAR EXHAUST GAS TEMPERATURE SENSOR

DIFFERENTIAL PRESSURE SENSOR – CDPF (EURO IV)

– REMOVAL AND INSTALLATION

FRONT EXHAUST GAS TEMPERATURE SENSOR – CDPF (EURO IV)

REAR EXHAUST GAS TEMPERATURE SENSOR – CDPF (EURO IV)

DIFFERENTIAL PRESSURE SENSOR – CDPF (EURO IV)

CDPF ASSEMBLY – CDPF (EURO IV)

CRUISE CONTROL SYSTEM

– OVERVIEW AND OPERATION PROCESS

1. CRUISE CONTROL SWITCH

2. CIRCUIT DIAGRAM

3. HOW TO OPERATE CRUISE CONTROL SWITCH

– REMOVAL AND INSTALLATION

CRUISE CONTROL SWITCH

ENGINE ASSEMBLY

– GENERAL

1. DESCRIPTION AND OPERATION

2. G23D ENGINE ASSEMBLY

3. G23D ENGINE STRUCTURE

4. DIAGNOSTIC INFORMATION AND PROCEDURE

5. GENERAL DIAGNOSIS

6. SPECIFICATIONS

– CONFIGURATION AND FUNCTIONS

CRANKCASE VENTILATION SYSTEM

OIL CIRCULATION

– REMOVAL AND INSTALLATION

ENGINE ASSEMBLY

ALTERNATOR

EINGINE MOUNT

POLY V-BELT

POLY V-BELT INSPECTION

TENSIONING DEVICE

TENSIONING DEVICE SHOCK ABSORBER

CYLINDER HEAD COVER

CYLINDER HEAD FRONT COVER

CYLINDER HEAD

TIMING GEAR CASE COVER

CRANKSHAFT SEALING REAR COVER

BELT PULLEY AND VIBRATION DAMPER

CRANKSHAFT FRONT RADIAL SEAL

CRANKSHAFT REAR RADIAL SEAL

CRANKSHAFT

ARRANGEMENT OF THE THRUST BEARING AND THE MAIN BEARING

FLYWHEEL/ DRIVE PLATE

CAMSHAFT ADJUSTER

CAMSHAFT

INSPECTION AND ADJUSTMENT OF CAMSHAFT TIMING POSITION

– REMOVAL AND INSTALLATION

VALVE SPRING

VALVE STEM SEAL

CHAIN TENSIONER

TIMING CHAIN

TENSIONING RAIL

CYLINDER HEAD GUIDE RAIL

CRANKCASE GUIDE RAIL

CRANKSHAFT SPROCKET

PISTON

CONNECTING ROD

PISTON RING

OIL PAN

ENGINE OIL AND OIL FILTER ELEMENT

OIL PUMP

OIL PRESSURE RELIEF VALVE

OIL NON-RETURN VALVE

OIL DIPSTICK GUIDE TUBE

REPAIR OF CORE PLUGS IN CRANKCASE

CYLINDER BORE

CRANKCASE MATING SURFACE

CYLINDER HEAD MATING SURFACE

ENGINE INTAKE SYSTEM

– GENERAL

1. SPECIFICATIONS

– CONFIGURATION AND FUNCTIONS

RESONANCE FLAP

AIR CLEANER AND INTAKE AIR DUCT

– REMOVAL AND INSTALLATION

AIR CLEANER AND INTAKE AIR DUCT

INTAKE MANIFOLD

ENGINE EXHAUST SYSTEM

– GENERAL

1. SPECIFICATION

– OVERVIEW AND OPERATION PROCESS

1. DESCRIPTION AND OPERATION

– REMOVAL AND INSTALLATION

EXHAUST LINE

ENGINE COOLING SYSTEM

– GENERAL

1. GENERAL SPECIFICATIONS

2. FASTENER TIGHTENING SPECIFICATIONS

– OVERVIEW AND OPERATION PROCESS

1. COMPONENT LOCATOR

2. DESCRIPTION AND OPERATION

3. PWM (PULSE WIDTH MODULATION) ELECTRIC FAN OPERATION

– REMOVAL AND INSTALLATION

DTC FOR PWM ELECTRIC FAN

DIAGNOSTIC INFORMATION AND PROCEDURE

REPAIR INSTRUCTIONS ONVEHICLE SERVICE

WATER PUMP

THERMOSTAT AND THERMOSTAT HOUSING ASSEMBLY

PWM CONTROLLER UNIT

PWM ELECTRIC FAN AND SHROUD ASSEMBLY

ENGINE ELECTRIC DEVICES

– GENERAL

1. DIAGNOSTIC INFORMATION AND PROCEDURE

– OVERVIEW AND OPERATION PROCESS

1. DESCRIPTION AND OPERATION

– REMOVAL AND INSTALLATION

GENERATOR REPAIR INSTRUCTIONS

STARTER REPAIR INSTRUCTIONS

BATTERY REPAIR INSTRUCTIONS

SPARK PLUG AND IGNITION COIL REPAIR INSTRUCTIONS

ELECTRIC GENERAL

– GENERAL

1. LOCATIONS OF INTERIOR UNITS AND SENSORS

2. LOCATION AND COMPARTMENT OF INTERIOR SWITCHES

3. SWITCHES, UNITS AND SENSORS IN ENGINE COMPARTMENT

4. ELECTRIC COMPONENTS AND LAYOUT

5. DIAGNOSTIC CONNECTOR

PAS

GENERAL

1. COMPONENT SPECIFICATIONS

2. CAUTIONS ON PARKING AID SYSTEM OVERVIEW AND OPERATION PROCESS

1. SYSTEM OVERVIEW

2. ALARM INTERVAL

3. TROUBLESHOOTING OF SENSOR

4. CIRCUIT DIAGRAM

– REMOVAL AND INSTALLATION

PARKING AID SENSOR

AUDIO SYSTEM

– OVERVIEW AND INSTALLATION

1. AUDIO SYSTEM OVERVIEW

2. CIRCUIT DIAGRAM OF AUDIO SYSTEM

– CONFIGURATION AND FUNCTION

COMBINATION ANTENNA

USB/AUX MODULE

– REMOVAL AND INSTALLATION

AV HEAD UNIT

FRONT DOOR SPEAKER AND REAR DOOR SPEAKER

DOOR TWEETER SPEAKER

COMBINATION ANTENNA

USB/AUX MODULE

FUSE AND RELAY

– GENERAL INFORMATION

1. GENERAL INFORMATION

– OVERVIEW AND OPERATING PROCESS

1. OVERVIEW

2. FUSE & RELAY MOUNTING LOCATION

3. CAPACITY AND NAME OF FUSE AND RELAY IN ENGINE COMPARTMENT

4. CAPACITY AND NAME OF INTERIOR FUSE AND RELAY

5. OPERATING PROCESS OF ICM BOX

– CONFIGURATION AND FUNCTIONS

CONFIGURATION OF PCB IN ICM BOX AND FUNCTION OF CONNECTOR

CIRCUIT DIAGRAM FOR FUSE & RELAY BOX IN ENGINE COMPARTMENT

CIRCUIT DIAGRAM FOR INTERIOR FUSE & RELAY BOX ON DRIVER SIDE

CIRCUIT DIAGRAM FOR INTERIOR FUSE & RELAY BOX ON PASSENGER SIDE

– REMOVAL AND INSTALLATION

ICM BOX

STICS

– GENERAL

1. OVERVIEW

2. MAJOR CHANGES

3. SPECIFICATIONS

– OVERVIEW AND OPEARATION PROCESS

1. OVERVIEW

2. FUNCTIONS AND SPECIFICATIONS

3. CIRCUIT DIAGRAM

– -REMOVAL AND INSTALLATION

REKES KEY CODING

DIAGNOSIS TROUBLE CODE AND HEIP TIPS

STICS

IMMOBILIZER SYSTEM

OVERVIEW AND OPERATION PROCESS

1. OVERVIEW

2. BASIC FUNCTIONS OF IMMOBILIZER KEY

3. OTHER FUNCTIONS IN SYSTEM

4. REKES OPERATION LOGIC

5. CIRCUIT DIAGRAM

– REMOVAL AND INSTALLATION

IMMOBILIZER CODING PROCEDURE

IMMOBILIZER UNIT

CLUSTER

– GENERAL

1. DESCRIPTIONS OF INDICATOR DISPLAY

2. WARNING & INDICATOR PANEL

3. CLUSTER OPERATION PROCESS

4. CIRCUIT DIAGRAM

– CONFIGURATION AND FUNCTIONS

COFIGURATION OF CLUSTER

– REMOVAL AND INSTALLATION

METER CLUSTER

LAMP

– OVERVEIW AND OPERATION PROCESS

1. LOCATIONS OF EXTERIOR LAMPS

2. INTERIOR LAMPS

3. LAMP OPERATION LOGIC

– CONFIGURATION AND FUNCTIONS

FRONT LAMPS

REAR LAMP

INTERIOR LAMPS

– REMOVAL AND INSTALLATION

HEAD LAMPS

FOG LIGHT

SIDE REPEATER

REAR COMBINATION LAMP

LICENSE PLATE LAMP

HIGH MOOUNTED STOP LAMP

REAR FOG LIGHT

INTERIOR LAMPS

SWITCH

– GENERAL

1. SWITCH ARRANGEMENT

– CONFIGURATION AND FUNCTIONS

CENTER FASCIA & BEZEL SWITCH ASSEMBLY

OUTSIDE REARVIEW MIRROR SWITCH BEZEL ASSEMBLY

INTERIOR LAMP SWITCH

MAIN POWER WINDOW SWITCH

AUDIO REMOTE CONTROL SWITCH ON STEERING WHEEL

MULTIFUNCTION SWITCH

TAIL GATE OPEN SWITCH

DIGITAL CLOCK

HORN (INCLUDING THEFT WARNING HORN)

– REMOVAL AND INSTALLATION

HAZARD & SWITCH ASSEMBLY

OUTSIDE REARVIEW MIRROR SWITCH BEZEL ASSEMBLY

OUTSIDE REARVIEW MIRROR FOLDING UNIT

OVERHEAD CONSOLE SWITCH

MAIN POWER WINDOW SWITCH

AUDIO REMOTE CONTROL SWITCH

MULTIFUNCTION SWITCH

TAIL GATE OPEN SWITCH

CIGARETTE LIGHTER

FRONT POWER OUTLET

REAR POWER OUTLET

DIGITAL CLOCK

HORN

WIPER & WASHER

– OVERVIEW AND OPERATION PROCESS

1. SYSTEM LAYOUT AND FUNCTION

2. SYSTEM LAYOUT OF WIPER AND WASHER (WITH RAIN SENSOR)

3. WIPER & WASHER RELATED FUNCTION AND SPECIFICATION

4. WIPER AND WASHER SYSTEM RELATED CIRCUIT DIAGRAM

– REMOVAL AND INSTALLATION

CORRECTION OF FRONT WIPER

FRONT WIPER ASSEMBLY

REAR WIPER ASSEMBLY

WASHER FLUID RESERVOIR TANK

WASHER NOZZLE

RAIN SENSOR

OVERVIEW AND OPERATION PROCESS

1. SYSTEM LAYOUT AND OVERVIEW

2. RAIN SENSING OPERATION

3. RAIN SENSOR RELATED CIRCUIT

4. FUNCTIONS AND SPECIFICATIONS OF RAIN SENSING WIPER

5. OPERATION MODE OF RAIN SENSING WIPER SYSTEM

– REMOVAL AND INSTALLATION

FUNCTIONS AND CHECKS OF RAIN SENSOR

DIAGNOSIS PROCEDURES

RAIN SENSOR

ION 4-SPEED

– GENERAL

1. SPECIFICATIONS

2. FASTENER TIGHTENING SPECIFICATIONS

– OVERVIEW AND OPERATION PROCESS

1. DESCRIPTION AND OPERATION OF AUTOMATIC TRANSMISSION

2. APPEARANCE

3. SHIFT PATTERN DIAGRAM

4. OPERATORS INTERFACES

5. CONTROL SYSTEMS

6. ELECTRONIC CONTROL SYSTEM

7. HYDRAULIC CONTROL SYSTEM

8. POWER FLOWS

– CONFIGURATION AND FUNCTIONS

TCU

ACCELERATOR PEDAL SENSOR

– REMOVAL AND INSTALLATION

DIAGNOSTIC INFORMATION AND PROCEDURES

REBUILD WARNINGS

FRONT AND REAR BAND ADJUSTMENT

SYMPTOM DIAGNOSIS

TROUBLE CODE DIAGNOSIS

ION AUTOMATIC TRANSMISSION ASSEMBLY

VALVE BODY

DISASSEMBLY OF TRANSMISSION

ASSEMBLY OF TRANSMISSION

3642-18 GEAR SHIFT CONTROL LEVER

TCU

STEERING

– GENERAL

1. OVERVIEW

2. SPECIFICATIONS

– OVERVIEW AND OPERATION

1. SYSTEM LAYOUT

2. COMPONENTS

– REMOVAL AND INSTALLATION

TROUBLE DIAGNOSIS

INSPECTIONS OF POWER STEERING SYSTEM

STEERING COLUMN SHAFT

LOWER SHAFT

STEERING GEAR BOX

STEERING GEAR PUMP

DSI M78 6-SPEED A/T

– GENERAL INFORMATION

1. DSI M78 6-SPEED AUTOMATIC TRANSMISSION GENERAL

2. STRUCTURE CHARACTERISTICS AND SPECIFICATIONS

3. TIGHTENING TORQUE

– OVERVIEW AND OPERATION PROCESS

1. GENERAL DESCRIPTION

2. ADVANCED SIX SPEED FEATURES

3. FUNCTION OF EACH MODE

4. LIMP HOME MODE

5. TRANSMISSION ELECTRONIC CONTROL SYSTEM

6. CONFIGURATION OF CAN RELATED TO TCU

7. POWER TRAIN

– CONFIGURATION AND FUNCTIONS

TGS LEVER

DSI M78 6-SPEED A/T ASSEMBLY

VALVE BODY

TCU

INHIBITOR SWITCH

– REMOVAL AND INSTALLATION

FLUID LEVEL INSPECTION

TRANSMISSION RESET PROCEDURE (REPLACEMENT TRANSMISSION)

– DIAGNOSIS AND TESTING

1. WIRING DIAGRAM

2. WIRE HARNESS CONNECTOR CHART

3. UNIT CONNECTOR DESCRIPTION

– TROUBLE CODE EIAGNOSIS

1. DIAGNOSTIC TROUBLE CODE LIST

2. SYSTEM DIAGNOSIS

– MAINTENANCE OPERATIONS

1. OIL TEST

2. STALL TEST

3. TRANSMISSION RESET PROCEDURE (REPLACEMENT TRANSMISSION)

4. FLUID LEVEL INSPECTION

5. TRANSMISSION COOLER AND HYDRAULIC LINE FLUSHING PROCEDURE

6. LUBRICATION

7. TRANSMISSION COOLER AND HYDRAULIC LINE FLUSHING PROCEDURE (NEW TRANSMISSION)

TGS LEVER

– OVERVIEW AND OPERATION PROCESS

1. INTRODUCTION

2. FUNCTIONS OF THE SELECTOR LEVER

3. MODE SWITCH

4. PARKING LOCK SYSTEM

– CONFIGURATION AND FUNCTIONS

SELECTOR LEVER CONTROL UNIT

– REMOVAL AND INSTALLATION

SHIFT ROD POSTION ADJUSTMENT

TGS LEVER

MANUAL TRANSMISSION

– GENERAL

1. OVERVIEW AND CHARACTERISTICS OF MANUAL TRANSMISSION

2. SPECIFICATIONS AND TIGHTENING TORQUE OF MANUAL TRANSMISSION

– OVERVIEW AND OPERATION PROCESS

1. MANUAL TRANSMISSION SYSTEM

– CONFIGURATION AND FUNCTIONS

MANUAL TRANSMISSION LOCATION

MANUAL TRANSMISSION SYSTEM COMPONENTS

SHIFTING MECHANISM

– REMOVAL AND INSTALLATION

DIAGNOSTIC INFORMATION AND PROCEDURES

OIL CHECK/CHANGE OF MANUAL TRANSMISSION

MANUAL TRANSMISSION

MANUAL TRANSMISSION OVERHAUL

TRANSMISSION ADAPTER

SHIM ADJUSTMENT

CLUTCH

– GENERAL

1. CLUTCH SPECIFICATIONS

2. TIGHTENING TORQUE

– OVERVIEW AND OPERATION PROCESS

1. FUNCTION AND OVERVIEW

– CONFIGURATION AND FUNCTIONS

CLUTCH MASTER CYLINDER

CLUTCH RELEASE CHAMBER

CLUTCH ASSEMBLY

CLUTCH PEDAL

– REMOVAL AND INSTALLATION

CLUTCH TROUBLE DIAGNOSIS

CLUTCH INSPECTION AND MAINTENANCE

CLUTCH AIR BLEEDING

CLUTCH ASSEMBLY

CLUTCH REPLACEMENT

CONCENTRIC SLAVE CTLINDER

CLUTCH MASTER CYLINDER

CLUTCH PEDAL

CLUTCH CHAMBER

AXLE

– GENERAL

1. SPECIFICATIONS OF AXLE

OVERVIEW AND OPERATION PROCESS

1. OVERVIEW OF AXLE

– CONFIGURATION AND FUNCTIONS

FRONT AXLE

5-LINK TYPE REAR AXLE

– REMOVAL AND INSTALLATION

TROUBLE DIAGNOSIS

INSPECTION OF RING GEAR TOOTH CONTACT PATTERN

FRONT AXLE ASSEMBLY

AXLE SHAFT

AXLE HOUSING

REAR AXLE SHAFT(DISC BRAKE TYPE)

REAR AXLE HOUSING

TRANSFER CASE

– GENERAL

1. OVERVIEW

2. SPECIFICATIONS

– OVERVIEW AND OPERATION PROCESS

1. STRUCTURE

2. SYSTEM LAYOUT AND OPERATION

3. LOCKING HUB SYSTEM

4. POWER FLOW

– CONFIGURATION AND FUNCTION

TRANSFER CASE

COMPONENTS OF IWE (INTEGRATED WHEEL END)

TCCU(TRANSFER CASE CONTROL UNIT)

– REMOVAL AND INSTALLATION

PART TIME TRANSFER CASE GENERAL DIAGNOSIS

VACUUM LOCKING HUB CHECK

OIL LEVEL CHECK AND CHANGE

SELF-DIAGNOSIS TEST

TCCU DIAGNOSTIC TROUBLE CODE

PART TIME TRANSFER CASE

TRANSFER CASE MOTOR

IWE (INTEGRATED WHEEL END)

LOCKING HUB ACTUATOR ASSEMBLY

TCCU

SUSPENSION

– GENERAL

1. SPECIFICATIONS OF SUSPENSION

2. WHEEL ALIGNMENT

– CONFIGURATION AND FUNCTION

FRONT SUSPENSION

REAR SUSPENSION (5-LINK TYPE)

– REMOVAL AND INSTALLATION

TROUBLE DIAGNOSIS OF REAR SUSPENSION

FRONT SUSPENSION-UPPER ARM

FRONT SUSPENSION- COIL SPRING & SHOCK ABSORBER ASSEMBLY

FRONT SUSPENSIONSTABILIZER BAR

FRONT SUSPENSIONLOWER ARM

REAR SUSPENSION (5 LINK TYPE)

ESP

– GENERAL

1. SYSTEM GENERAL

2. SECTIONAL DRAWING

3. SPECIFICATIONS

4. BRAKE OPERATION AND NOISE

5. ESP SYSTEM RELATED PRECAUTIONS

– OVERVIEW AND OPERATION PROCESS

1. OVERVIEW OF ESP(ELECTRONIC STABILITY PROGRAM) SYSTEM

2. COMPONENTS OF ESP

3. PRINCIPLE OF ESP

4. PRINCIPLE OF BAS(BRAKE ASSIST SYSTEM)

5. PRINCIPLE ARP(ACTIVE ROLL-OVER PROTECTION)

6. PRINCIPLE OF HDC(HILL DESCENT CONTROL)

7. INPUT AND OUTPUT DIAGRAM OF ESP SYSTEM

8. HYDRAULIC CIRCUIT DIAGRAM OF ESP SYSTEM

9. HYDRAULIC PRESSURE FOR EACH ESP OPERATING RANGE

10. HYDRAULIC CIRCUIT OF BAS (BRAKE ASSIST SYSTEM)

11. COMPONENTS OF ABS SYSTEM

– CONFIGURATION AND FUNCTIONS

HECU OF ESP

HECU OF ABS

PRESSURE SENSOR

SENSOR CLUS

SWAS(STEERING WHEEL ANGLE SENSOR)

ESP OFF SWITCH

ASS(Active Wheel Speed Sensor)

– REMOVAL AND INSTALLATION

ESP SYSTEM AIR BLEEDING

SENSOR CALIBRATION AND FORCED OPERATION OF ACTUATOR SENSOR VALUE

ABS/ESP TROUBLE DIAGNOSIS

CAUTIONS WHEN REMOVING FRONT WHEEL SPEED SENSOR-ESP

CAUTIONS WHEN REMOVING FRONT WHEEL SPEED ABS

HECU-ESP

HECU-ABS

FRONT WHEEL SPEED SENSOR

REAR WHEEL SPEED SENSOR

PRESSURE SENSOR

SENSOR CLUSTER

AIR BAG

– GENERAL

1. OVERVIEW (INCLUDING CURTAIN AIR BAGS)

– OVERVIEW AND OPERATION PROCESS

1. LOCATION AND RELATED COMPONENTS

2. AIR BAG SYSTEM OPERATION PROCESS

3. AIR BAG MODULE AND RELATED COMPONENTS

– REMOVAL AND INSTALLATION

TROUBLE

DRIVER AIR BAG

PASSENGER AIR BAG

CURTAIN AIR BAG

CONTACT COIL

AIR BAG(SDM)

CURTAIN AIR BAG G SENSOR

SEAT

– OVERVIEW AND OPERATION PROCESS

1. COMPOSITION OF SEAT

2. FUNCTIONS OF SEAT

3. COMPONENTS OF SEAT BELT

– REMOVAL AND INSTALLATION

SEAT MOUNTING POINTS

SEAT ASSEMBLY

SEAT BELT

SUNROOF

– OVERVIEW AND OPERATION PROCESS

1. COMPONENTS AND LOCATIONS

2. OPERATION AND FUNCTION

– CONFIGURATION AND FUNCTION

COMPONENTS OF SUNROOF

– REMOVAL AND INSTALLATION

RESETTING OF SUNROOF CONTROL UNIT

TROUBLE DIAGNOSIS

GLASS PANEL ASSEMBLY

BELLOWS COVER

DRAIN CHANNEL

SUN SHADE PANEL

SUNROOF CONTROL UNIT(SCU) AND MOTO

SUNROOF DRAIN HOSE

SUNROOF ASSEMBLY

BODY INTERIOR

– OVERVIEW AND OPERATION PROCESS

1. LOCATIONS

– REMOVAL AND INSTALLATION

INSTRUMENT PANEL ASSEMBLY

INSTRUMENT PANEL FRAME ASSEMBLY

CENTERCONSOLE (AUTOMATIC TRANSMISSION)

CENTER CONSOLE (MANUAL TRANSMISSION)

SUNVISOR

PILLAR

HEADLINING ASSEMBLY

OUTSIDE REARVIEW

MIRROR

INSIDE REARVIEW MIRROR

BODY EXTERIOR

– OVERVIEW AND OPERATION PROCESS

1. COMPOSITION OF BODY EXTERIOR

– CONFIGURATION AND FUNCTION

COMPONENT OF FRONT BUMPER ASSEMBLY

COMPONENTS OF REAR BUMPER ASSEMBLY

COMPONENTS OF HOOD ASSEMBLY

COMPONENTS OF SIDE SILMOLDING

COMPONENTS OF FRONT DOOR ASSEMBLY

COMPONENTS OF FRONT WINDOW REGULATOR

COMPONENTS OF REAR DOOR ASSEMBLY

COMPONENTS OF REAR WINDOW REGULATOR

COMPONENTS OF TAILGATE ASSEMBLY

– REMOVAL AND INSTALLATION

HOOD ASSEMBLY

SIDE SILMOLDING

FENDER PANEL ASSEMBLY

FRONT DOOR TRIM (DRIVER SIDE)

FRONT DOOR (DRIVER SIDE)

WINDOW REGULATOR (PASSENGER SIDE)

REAR DOOR TRIM

REAR DOOR ASSEMBLY

REAR DOOR MOLDING AND PANEL

REAR WINDOW REGULATOR

TAILGATE TRIM

TAILGATE ASSEMBLY

TAILGATE LATCH AND ACTUATOR

REAR QUARTER GLASS

BODY REPAIR

– GENERAL

1. DIMENSIONS

2. JACK-UP POINTS

3. DESIGN CHANGES FOR IMPROVING NVH PERFORMANCE

– CONFIGURATION AND FUNCTIONS

FRAME DIMENSIONS

FRAME BODY MOUNTING

WHITE BODY

BODY DIMENSIONS

BODY GAPS

DOOR COMPONENTS(INCLUDING ENGINE HOOD)

COMPONENTS OF BODY PANELS

AIR CONDITIONER

OVERVIEW AND OPERATION PROCESS

1. SYSTEM LAYOUT AND COMPONENTS

2. VENTILATION SYSTEM

3. AIR CONDITIONER MODULE AND SENSORS

4. SYSTEM DIAGRAM

– CONFIGURATION AND FUNCTIONS

AIR CONDITIONER CONTROLLER UNIT

SUNSENSOR

ACTIVE INCAR / HUMIDITY SENSOR: AI SENSOR

AMBIENT TEMPERATURE SENSOR

WATER TEMPERATURE SENSOR

POWER TRANSISTOR

MODE DOOR ACTUATOR

IN/EX – AIR DOOR ACTUATOR

AIR MIX DOOR ACTUATOR

THERMO AMP (INTAKE SENSOR)

FFH (FUEL FIRED HEATER) SYSTEM

PTC(POSITIVE TEMPERATURE COEFFICIENT)

SELF DIAGNOSIS (ONLY FOR FATC A/C CONTROLLER)

TROUBLE DIAGNOSIS

AMBIENT TEMPERATURE SENSOR

WATER TEMPERATURE SENSOR

POWER TRANSITOR

MODE DOOR ACTUATOR

IN/EX-AIR DOOR ACTUATOR

AIR MIX DOOR ACTUATOR

THERMO AMP (INTAKE SENSOR)

AIR CONDITONER MODULE ASSEMBLY

A/C CONTROLLER SWITCH AND ACTIVE INCAR/HUMIDITY SENSOR

AIR DUCT ASSEMBLY

CONDENSER ASSEMBL

RECEIVER DRYER ASSEMBLY

FUEL PUMP

AMBIENT TEMPERATURE SWITCH

FFH ASSEMBLY

PTC

ECU-GASOLINE

DIAGRAMS AND CONECTORS

Aplicação: 2011-2015

Idioma: Inglês

Tamanho: 128.9Mb

Tipo: PDF

Índice

Informações gerais

Suspensão Dianteira

Suspensão Traseira

Rodas e Pneus

Eixo de Transmissão

Eixo Traseiro /Diferencial

Eixo Dianteiro /Diferencial

Semi Eixo de Tração Dianteira

Semi Eixo de Tração Traseira

Sistema de Freio Dianteiro e Traseiro

Freio de Estacionamento e Atuador

ABS e Controle de Tração

Sistema de Direção

Motor

– Engine2.5L Duratec-HE

– Engine2.2L Duratorq-TDCi

– Engine3.2L Duratorq-TDCi

Transmissão

– Manual

– Automática

Macaco e Elevador

Barulho, Vibrações e Asperezas

Painel de Instrumentos e Console

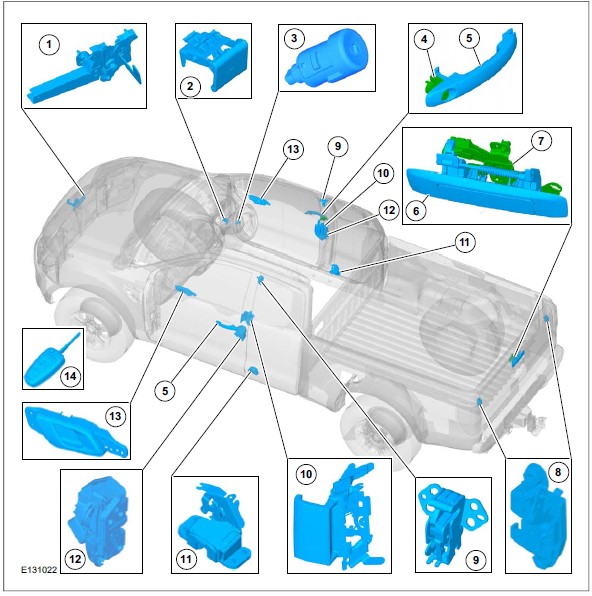

Maçanetas, Travas, Fechaduras

Limpadores e Lavadores

Para Choques

Cinto de Segurança

Air Bag

Reparo de Carroceria

Pintura

Puxadores e Ornamentos

Paineis Interiores

Bancos

Vidros

Diagrama Elétrico e Conectores

https://loja.webautomotivo.com.br/produto/seja-um-associado/

Ford Mondeo 2001 10.2000-02.2007 Manual de oficina ((10.2000-02.2007))

Manuais de oficina Ford: Reparos mecânicos, Informações gerais, Informações de serviço, , Descrição e operação, Sobre este manual

https://loja.webautomotivo.com.br/produto/seja-um-associado/

Tamanho: 450 Mb

Tipo: PDF

Aplicação: Sistemas Honda

Idioma: Inglês

ÍNDICE

2018 Civic Type R–PDI Information

2018 Civic Hatchback – PDI Information

2018 Civic Hatchback–PDI of the Navigation System

2018 Civic Type R–PDI of the Navigation System

Adaptive Damper System

Audio and Visual System

Body and Paint

Body Control Module

Body Repair

Brake System

Bumpers

CAN Communications

Catalytic Converter System

Charging System

Civic Hatchback Owner’s Guide

Climate Control System

Clutch

Cruise Control System

CVT System

Dashboard Center Console

Doors

Driveline-Axle

Driving Support System

DTC Advanced Diagnostics

DTC Index _ Troubleshooting

Electric Parking Brake System

Electrical Wiring Diagrams

Electronic Throttle Control System

Engine Cooling System

Engine Exhaust System

Engine Lubrication System

Engine Mechanical System

EVAP System

Exterior Trim

Front and Rear Suspension

Fuel and Emissions Systems

Fuel Supply System

Gauges System

Honda Civic (FC-FK) 2016-2019 Service Repair Manual

Horn System

HVAC

Ignition System

Immobilizer System

Intake Air System and Exhaust System

Interior Trim

Keyless Access System

Lane Keeping Assist System (LKAS)

Lighting System

Maintenance Minder

Manual Transmission

Moonroof System

Navigation System

PCV System

Personalized Setting Worksheet

PGM-FI System

Power Mirrors

Power Steering

Power Window

Seat Belts System

Seat System

Service-General Information

Socket-Fuse-Relay-Switch

SRS Airbag System

Starter Overhaul.

Steering Wheel and Column

Tailgate System

TCM

TPMS System

Trunk-Lid-Hood

Turbocharger Control System

Volt Battery Removal and Installation

VSA System

Wheel _ Tire System

Windows Glass and Mirorrs

Wipers-Washers

Wire Harness and Ground Locations

https://loja.webautomotivo.com.br/produto/seja-um-associado/

Tamanho: 60.4 Mb

Tipo: PDF

Idioma: Português

ÍNDICE

MECÂNICA

– Ficha Técnica

– Informação do Veiculo

– Sistema Mecânicos

– Torques de aperto

– Substituição da Correia Dentada

– Cabeçote do Motor

– Suspensão

– Sistema de Arrefecimento

– Substituição da Bomba d’água

– Substituição da Válvula Termostática

– Sistema de Alimentação de combustível e recuperação

– Tanque de combustível

– Bomba de Combustível

– Modulo de Comando da Carroceria

ELÉTRICA

– Caixa de relê e fusível central

– Caixa de reles do BCM

– Pontos de Aterramentos

– Painel de Controle

– Interruptores

– Conectores

– Motor de partida

– Sistemas Elétricos

– Imobilizador

INJEÇÃO ELETRÔNICA

– Apresentação do Sistema de Injeção Eletrônica

– Localização dos componentes do sistema de injeção eletrônica

– Osciloscópio Digital

– Recursos do Scanner

– Modulo de Comando

– Sensor de Oxigênio – Hego

– Sensor de temperatura de líquido Arrefecimento

– Conjunto medidor de densidade

– Sensor de posição da borboleta

– Atuador da marcha Lenta

– Sensor de posição da arvore de manivelas

– Aterramento da malha de blindagem

– Eletroinjetores de Combustível

– Eletroválvula de purga do Canister

– Bobina de Ignição

– Sensor de velocidade

– Sensor de detonação

– Sistema de partida a frio – SPF

– Tabela de Valores ideais

– Diagrama Elétrico Flex Power

https://loja.webautomotivo.com.br/produto/seja-um-associado/

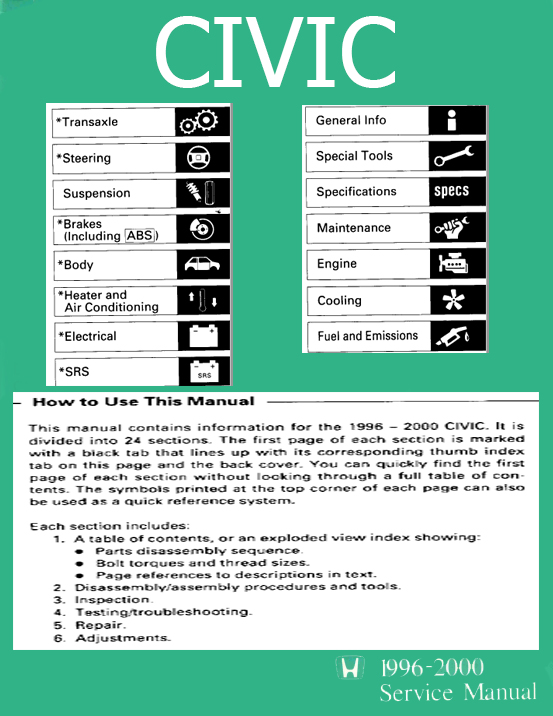

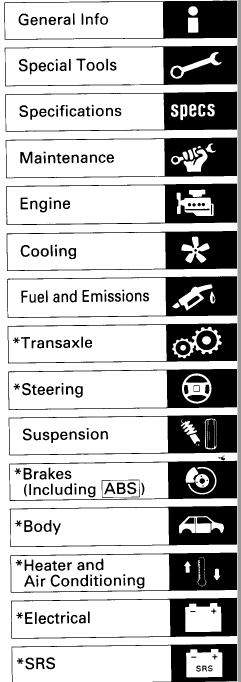

Manual de serviço para Honda Civic entre os anos de 1996 à 2000

ÍNDICE

Imagens demonstrativas

https://loja.webautomotivo.com.br/produto/seja-um-associado/

Tamanho: 345 Mb

Tipo: Navegador

Idioma: Inglês

ÍNDICE – (complemento do índice no fim da página)

– Especificações

– Métricas

– Fórmulas do adaptador de chave de torque

– Índice Alfabético

1: Informações Gerais

– Serviço de informação

2: Chassi

– Suspensão

– Linha de direção

– Sistema de travagem

– Sistema de direção

3: Trem de força

– Motor

– Transmissão automática

– Caixa de transmissão manual, embreagem e transferência

– Sistema de exaustão

– Sistema de combustível – informações gerais

4: Elétrico

– Sistema de Controle Climático

– Sistemas de instrumentação e alerta

– Bateria e sistema de carregamento

– Sistemas de Informação e Entretenimento

– Iluminação

– Distribuição Elétrica

– Grupo de Recursos Eletrônicos

5: Carroceria e Pintura

– Corpo e Pintura

– Quadro e montagem

https://loja.webautomotivo.com.br/produto/seja-um-associado/